23.5-25 Extra-Strength Tire Protection Chain

Open pit mining

Underground mining

Quarrying

Salg and scrap handing

High-temperature surfaces

Traction

Wet or slippery surfaces

MATERIAL

Link:40Cr

Ring:20CrMnTi

WHAT IS TIRE PROTECTION CHAIN?

A Tire Protection Chain is a close mesh of high-alloy, drop-forged, steel, wear links which wraps around the tire to protect the tread and sidewalls. The flexible nature of the mesh enables the chain to adjust to the tire as it deforms during the loading or hauling operation. The chain´s highly-efficient, self-cleaning properties prevents the mesh from becoming filled and clogged thus achieving the best possible traction and increasing the loader´s productivity.

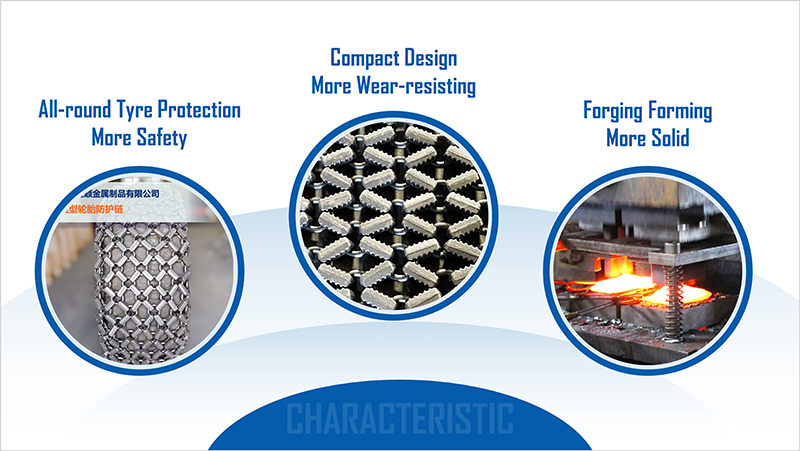

CHARACTERISTIC

TIRE SIZE

| TIRE SIZE | |

16/70-20 | 29.5-29 |

16/70-24 | 750/65R25 |

17.5-25 | 35/65-33 |

18.00-25 | 45/65-45 |

20.5-25 | 55.5/80-57 |

23.5-25 | 58/85-57 |

26.5-25 | 27.00R49 |

29.5-25 | 70/70-57 |

Remarks: 1.Tire protection chain including but not limited to the above specifications. Tire protection chain could be design according to your tire. 2.Our company has the world’s widest product range and can supply the ideal tire protection chain for all types of machine and applications. | |

OUR ADVANTAGES

1. Forging design

The R&D team specializing in forging parts designs and develops its own forging processes, analyzes the structural features of forged parts, and continuously optimizes and improves quality.

2. High quality raw materials

Only the best materials from large-scale steel mill, such as 40Cr and 20CrMnTi, are selected for production. Some other manufacturers are used scrap rebar or non-standard 45# steel, in order to reduce cost. We strictly control the quality of each component from the source. Only after thorough inspection of the raw materials can they be allowed to enter the factory.

3. Focus on process details

The process of straightening and normalizing the ring parts greatly improves the comprehensive mechanical properties of raw materials. After carburizing, the workpiece is quenched and tempered at low temperature, so that the surface has high hardness and wear resistance, while the heart still maintains good plasticity and toughness, so as to meet the requirements of the use of the workpiece.

4. Strictly control product quality

There are a number of quality tests for each finished product, in order to ensure the product quality. The static tensile strength (KN) is 50° without deformation. The Rockwell hardness (HRC) of the ground working surface is 48-52 degrees.

.png)